Top-class sauna world

Oriental Bath at Aachen's Carolus Thermen modernized with PCI building materials

Products used

Top-class sauna world

Oriental Bath at Aachen's Carolus Thermen modernized with PCI building materials

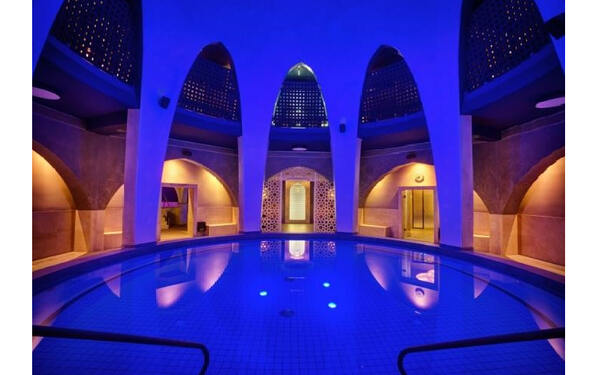

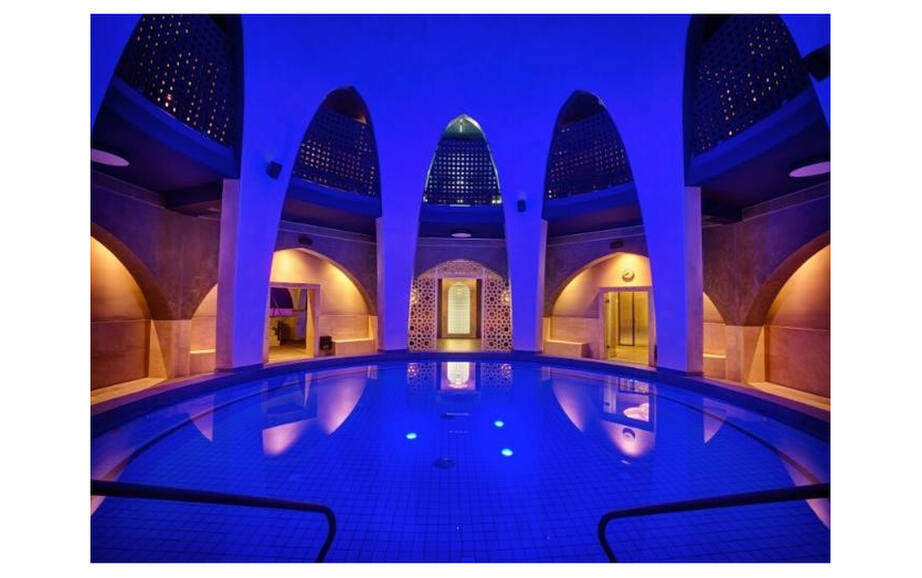

Tradition obliges: Even 2,000 years ago, the Romans appreciated the beneficial effects of Aachen's thermal springs. In later days, Charlemagne liked to visit the city's baths frequently - the name of the Carolus Thermen is a reminder of this to this day. In the sophisticated redesign of their oriental bathing world, skilled craftsmanship was combined with high-quality building materials. The result: top quality, filigree craftsmanship and a timeless look.

The Carolus Thermen in Aachen is a modern premium thermal spa with an extensive sauna area. The facility was opened in 2001 and has been extensively renovated and redesigned since 2017. The entire site measures around 13,000 m². A total of six saunas, three sanariums and three steam baths as well as several pools are available to around 1,000 bathers every day. The spacious sauna world consists of the Baltic Sauna World, the Oriental Bathing World, the Sauna Garden and the Feminarium, a separate women's sauna area. Initially, the Kur- und Badegesellschaft mbH, the operator of the Carolus Thermen, planned urgent renovation and repair work in the Oriental Bath for 2020. Over time, however, this plan turned into a major project that made the local craftspeople sweat - in every respect.

High-quality renovation with PCI building materials and a timeless look

Björn Jansen, Managing Director of Carolus Thermen, commissioned the specialist tiling company Keramikbau Kessels GmbH from Aachen to modernize the Oriental Bathing World. Thomas Kessels relied on PCI's technical expertise and system solutions for the demanding tiling work. Right from the start, PCI specialist consultant Marcus Mielczarek was on hand as a competent partner. "We had clear ideas for the renovation and high standards for the craftsmanship and quality of the building materials used," says Björn Jansen. "We wanted a timeless and elegant design that would delight guests in our thermal spa for years to come." The choice therefore fell on modern, large-format tiles with a natural stone look and barely visible joints. Wet areas in particular place high demands on the craftsmanship and the product systems used. For Thomas Kessels, the choice of building materials was therefore clear from the start. He explains: "I have found PCI solutions to be absolutely reliable in such environments. I also appreciate the expert advice and support provided by the PCI application technician throughout the entire project."

The spatial geometry of the Oriental Bath made the project a particular challenge: the area is designed as an octagon around a central relaxation pool. Starting from a circular pool in the center, the flooring made from fully-vitrified tiles was laid around the pool in such a way that the joints lead outwards to the other rooms in a star shape. This sophisticated joint pattern also places higher demands on the laying mortar meaning that the products used not only had to meet the corresponding water exposure classes, but also the challenging, angled room geometry. In addition, there were demanding details such as heated benches and the plunge pools in the adjacent Roman Bath.

Perfect basis for sophisticated tile laying

Proper waterproofing is essential for the quality and durability of the tile installation. In addition to specialist knowledge and craftsmanship, the bonded waterproofing also required the use of products that are suitable for the very high water exposure.

The tilers used the fast-setting waterproofing slurry PCI Seccoral 2K Rapid on the walls and floors of all areas exposed to moisture in the central relaxation pool of the Oriental Bath. The bonded waterproofing is stress-relieving and crack-bridging and therefore offers a high level of reliability even in the event of cracks occurring in the substrate at a later date. It is suitable for all water exposure classes without chemical stress.

Precision work in the pool surround

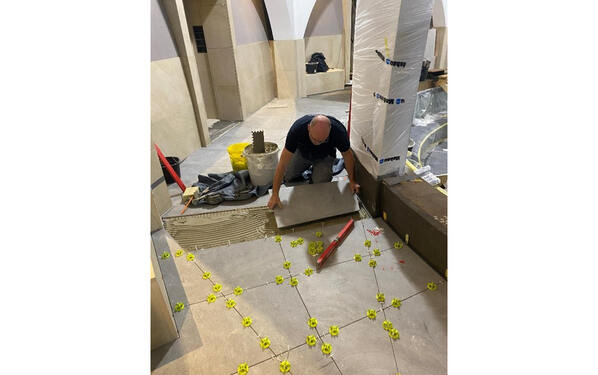

Tiles in the format 60 x 120 cm were used for the pool surround of the Oriental Bath. However, not a single one was installed in this format: Due to the special octagonal shape of the room, all tiles were cut to size individually and precisely. This resulted in a cut length of over 500 meters of visible cuts on an area of just 80 m². These also had to be cut and edged by machine to eliminate the risk of injury to bathers with sharp edges in the barefoot area.

The pool surround consists of eight sections. Each of these has a central floor drain that collects water sloshing out of the pool. In order to create the required gradient, the craftspeople had to fit, lay and grout the mitered tiles very precisely. "With such a symmetrical design, even the smallest errors are immediately visible. Our tilers were very focused and worked with millimeter precision. During the entire construction phase, PCI specialist consultant Markus Mielczarek and application engineer Jörg Hilden were always on hand to provide us with their expertise," emphasizes Thomas Kessels.

Reliable building materials from PCI

The individual cut-to-size fitting pieces had to be laid over the entire surface and positioned very precisely without excess laying mortar rising up in the joint chambers. The experts used the flexible tile adhesive PCI Flexmörtel S1 Flott particularly suitable for laying large-format fully-vitrified tiles on the floor and combining a very long working time with very fast-setting properties. Its stable adhesive bed prevents heavy tiles from sinking in.

The ceramic coverings were grouted with PCI Durapox Premium. The epoxy resin grout can be grouted almost as smoothly and easily washed as a cementitious grout. As it is impermeable to water and resistant to chemicals, it is the ideal product for permanently wet areas and surfaces that are frequently subjected to intensive cleaning.

Self-made "natural stone slabs" on PCI PowerBoard as the substructure

To round off the overall look, heated benches with a natural stone look were planned on all sides of the octagonal pool surround. Here too, the specialist tiling company demonstrated its creativity and know-how: PCI PowerBoard HR foam boards with a thickness of 5 cm form the raw shape of the benches. A recess was made in the boards in which the heating system was installed and grouted with PCI Periplan Extra. The flexible waterproofing membrane PCI Pecilastic W was bonded on top for waterproofing and protection. Large-format ceramic tiles with a natural stone look were then laid using PCI Flexmörtel S1 Flott, also mitered. Thanks to the fact that they were joined at the appropriate angle, without rails or joints, the benches look as if they were made from a single thick slab of natural stone. The advantage: the ceramic surface is robust and easy to clean.

Special challenge: the Roman Bath

Adjacent to the Oriental Bath are further bathing rooms, including a Roman Bath, where bathers can relax in the thermal water of the Aachen Rose Spring. This mineral-rich water requires particularly intensive cleaning to reliably remove all deposits. The requirements for the durability of the materials used for waterproofing, laying and grouting in this area were very high. The plunge pools of the Roman Bath were first primed with PCI Epoxigrund 390 and then waterproofed with PCI Apoflex W on the walls and PCI Apoflex F on the floor. The polyurethane waterproofing is highly resistant and therefore also suitable for saltwater pools and thermal baths. The ceramic tiles were laid and grouted with PCI Durapox Premium epoxy resin mortar to ensure chemical resistance and a structurally tight joint.

Close exchange and fast progress

Very close cooperation between client, architect, craftspeople and PCI enabled quick decisions and rapid work. "As one of the top 5 premium sauna landscapes in Germany, we had high demands on the renovation. Thanks to the professional workmanship, expert advice and quality products from PCI, these were fully met," summarizes Björn Jansen.

The Carolus Thermen in Aachen is a modern premium thermal spa with an extensive sauna area. The facility was opened in 2001 and has been extensively renovated and redesigned since 2017. The entire site measures around 13,000 m². A total of six saunas, three sanariums and three steam baths as well as several pools are available to around 1,000 bathers every day. The spacious sauna world consists of the Baltic Sauna World, the Oriental Bathing World, the Sauna Garden and the Feminarium, a separate women's sauna area. Initially, the Kur- und Badegesellschaft mbH, the operator of the Carolus Thermen, planned urgent renovation and repair work in the Oriental Bath for 2020. Over time, however, this plan turned into a major project that made the local craftspeople sweat - in every respect.

High-quality renovation with PCI building materials and a timeless look

Björn Jansen, Managing Director of Carolus Thermen, commissioned the specialist tiling company Keramikbau Kessels GmbH from Aachen to modernize the Oriental Bathing World. Thomas Kessels relied on PCI's technical expertise and system solutions for the demanding tiling work. Right from the start, PCI specialist consultant Marcus Mielczarek was on hand as a competent partner. "We had clear ideas for the renovation and high standards for the craftsmanship and quality of the building materials used," says Björn Jansen. "We wanted a timeless and elegant design that would delight guests in our thermal spa for years to come." The choice therefore fell on modern, large-format tiles with a natural stone look and barely visible joints. Wet areas in particular place high demands on the craftsmanship and the product systems used. For Thomas Kessels, the choice of building materials was therefore clear from the start. He explains: "I have found PCI solutions to be absolutely reliable in such environments. I also appreciate the expert advice and support provided by the PCI application technician throughout the entire project."

The spatial geometry of the Oriental Bath made the project a particular challenge: the area is designed as an octagon around a central relaxation pool. Starting from a circular pool in the center, the flooring made from fully-vitrified tiles was laid around the pool in such a way that the joints lead outwards to the other rooms in a star shape. This sophisticated joint pattern also places higher demands on the laying mortar meaning that the products used not only had to meet the corresponding water exposure classes, but also the challenging, angled room geometry. In addition, there were demanding details such as heated benches and the plunge pools in the adjacent Roman Bath.

Perfect basis for sophisticated tile laying

Proper waterproofing is essential for the quality and durability of the tile installation. In addition to specialist knowledge and craftsmanship, the bonded waterproofing also required the use of products that are suitable for the very high water exposure.

The tilers used the fast-setting waterproofing slurry PCI Seccoral 2K Rapid on the walls and floors of all areas exposed to moisture in the central relaxation pool of the Oriental Bath. The bonded waterproofing is stress-relieving and crack-bridging and therefore offers a high level of reliability even in the event of cracks occurring in the substrate at a later date. It is suitable for all water exposure classes without chemical stress.

Precision work in the pool surround

Tiles in the format 60 x 120 cm were used for the pool surround of the Oriental Bath. However, not a single one was installed in this format: Due to the special octagonal shape of the room, all tiles were cut to size individually and precisely. This resulted in a cut length of over 500 meters of visible cuts on an area of just 80 m². These also had to be cut and edged by machine to eliminate the risk of injury to bathers with sharp edges in the barefoot area.

The pool surround consists of eight sections. Each of these has a central floor drain that collects water sloshing out of the pool. In order to create the required gradient, the craftspeople had to fit, lay and grout the mitered tiles very precisely. "With such a symmetrical design, even the smallest errors are immediately visible. Our tilers were very focused and worked with millimeter precision. During the entire construction phase, PCI specialist consultant Markus Mielczarek and application engineer Jörg Hilden were always on hand to provide us with their expertise," emphasizes Thomas Kessels.

Reliable building materials from PCI

The individual cut-to-size fitting pieces had to be laid over the entire surface and positioned very precisely without excess laying mortar rising up in the joint chambers. The experts used the flexible tile adhesive PCI Flexmörtel S1 Flott particularly suitable for laying large-format fully-vitrified tiles on the floor and combining a very long working time with very fast-setting properties. Its stable adhesive bed prevents heavy tiles from sinking in.

The ceramic coverings were grouted with PCI Durapox Premium. The epoxy resin grout can be grouted almost as smoothly and easily washed as a cementitious grout. As it is impermeable to water and resistant to chemicals, it is the ideal product for permanently wet areas and surfaces that are frequently subjected to intensive cleaning.

Self-made "natural stone slabs" on PCI PowerBoard as the substructure

To round off the overall look, heated benches with a natural stone look were planned on all sides of the octagonal pool surround. Here too, the specialist tiling company demonstrated its creativity and know-how: PCI PowerBoard HR foam boards with a thickness of 5 cm form the raw shape of the benches. A recess was made in the boards in which the heating system was installed and grouted with PCI Periplan Extra. The flexible waterproofing membrane PCI Pecilastic W was bonded on top for waterproofing and protection. Large-format ceramic tiles with a natural stone look were then laid using PCI Flexmörtel S1 Flott, also mitered. Thanks to the fact that they were joined at the appropriate angle, without rails or joints, the benches look as if they were made from a single thick slab of natural stone. The advantage: the ceramic surface is robust and easy to clean.

Special challenge: the Roman Bath

Adjacent to the Oriental Bath are further bathing rooms, including a Roman Bath, where bathers can relax in the thermal water of the Aachen Rose Spring. This mineral-rich water requires particularly intensive cleaning to reliably remove all deposits. The requirements for the durability of the materials used for waterproofing, laying and grouting in this area were very high. The plunge pools of the Roman Bath were first primed with PCI Epoxigrund 390 and then waterproofed with PCI Apoflex W on the walls and PCI Apoflex F on the floor. The polyurethane waterproofing is highly resistant and therefore also suitable for saltwater pools and thermal baths. The ceramic tiles were laid and grouted with PCI Durapox Premium epoxy resin mortar to ensure chemical resistance and a structurally tight joint.

Close exchange and fast progress

Very close cooperation between client, architect, craftspeople and PCI enabled quick decisions and rapid work. "As one of the top 5 premium sauna landscapes in Germany, we had high demands on the renovation. Thanks to the professional workmanship, expert advice and quality products from PCI, these were fully met," summarizes Björn Jansen.

Date

02.07.2024

Task

Modernizing the Oriental Bathing World

City

Aachen

Completion

2023

Products used

PCI Apoflex® W, PCI Periplan® Extra, PCI Epoxigrund 390, PCI Pecilastic® W, PCI Apoflex® F, PCI Seccoral® 2K Rapid, PCI Flexmörtel® S1 Flott, PCI Durapox® Premium, PCI PowerBoard boards

Specialist advice

PCI specialist consultant Marcus Mielczarek, PCI application engineer Jörg Hilden

Owner

Kur- und Badegesellschaft mbH

Company

Keramikbau Kessels GmbH

Your contact for inquiries:

PCI Augsburg GmbH

Piccardstraße 11, 86159 Augsburg

Telefon: 0821 5901-0

Telefax: 0821 5901-416

E-Mail: pci-info@pci-group.eu

www.pci-augsburg.de