Construction of the century: the Channel Tunnel

30 years of reliable connection - PCI and Sika products in the Channel Tunnel

Construction of the century: the Channel Tunnel

30 years of reliable connection - PCI and Sika products in the Channel Tunnel

On May 6, 1994, the time had come: the Channel Tunnel was opened with a festive ceremony. It has now been connecting Great Britain and France for 30 years - despite Brexit. One component of this engineering masterpiece is the performance grout PCI Vergussmörtel 50*. And: Sika was also involved in the construction of the Channel Tunnel.

The history of the Channel Tunnel dates back to the 19th century when the first plans for a fixed connection between England and France were developed. But it took more than 180 years before the project was actually started. In 1986, British Prime Minister Margaret Thatcher and French President François Mitterrand signed the contract to build the Channel Tunnel. Construction began the following year.

A technical challenge

With a total length of around 50 kilometers, including 38 kilometers under the sea, the Channel Tunnel is one of the longest underwater tunnels in the world. Construction at this depth and length placed enormous demands on the construction process. The engineers had to use state-of-the-art technology to bore the tunnel through the English Channel.

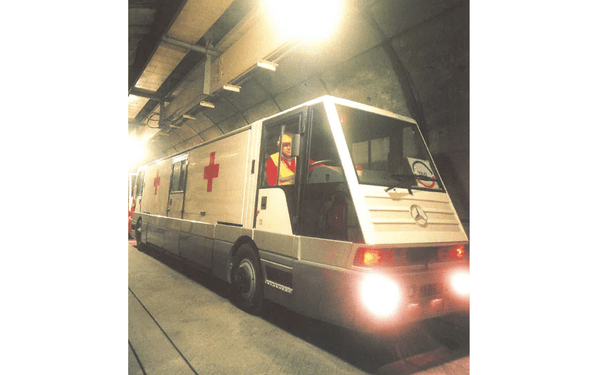

The Channel Tunnel comprises three tubes: two for rail traffic and a service tunnel. The service tunnel serves as a safe escape route for passengers and staff, houses important infrastructure for ventilation and enables regular inspections, repairs and maintenance work - without disrupting regular train traffic. In September 1991 and March 1992, PCI advised the builders on the performance grout for the cable grooves in the service tunnel.

Grouting cable grooves in the service tunnel

Cable grooves were integrated into the floor of the service tunnel to lay electrical cables. These cables were used to supply power to inductively guided special vehicles from AEG. Two grooves were milled into each of the existing tracks of the service tunnel. The workers inserted copper cables with PVC hard sheathing into these grooves. These were routed from one carriageway to the other every 2.25 km to enable the crossover sections to be crossed as planned. The cable grooves were then sealed by grouting the joints.

Resistant performance grout from PCI

The English-French construction committee placed strict requirements on the material required. The performance grout had to withstand the load caused by the vehicles regularly driving over it with a total weight of approx. 9 tons. It also had to be non-flammable and able to withstand temperatures from -10 °C to +45 °C. And it had to withstand the salty air with a relative humidity of between 30% and 90%.

Based on these requirements, PCI recommended the performance grout PCI Vergussmörtel 50*. The company Otto Alte-Teigeler GmbH Spezialbau Verkehrsflächen carried out the job on site and filled the grooves with the colored PCI Vergussmörtel 50* performance grout after the cables had been laid. From June 1993 to October 1993, between 5,000 and 6,000 meters were completed every day. In a total of 11,500 hours of precision work, 202,000 meters of induction joints were filled with millimeter precision using laser technology and 15 x 30 mm diamond tools developed for this purpose at the time.

While PCI made the cable grouting in the service tunnel possible with high-quality, permanently functional performance grout, Sika supported the construction of the Channel Tunnel with concrete admixtures for segments and concrete repair products.

Quality that lasts

Since its opening, the Channel Tunnel has developed into an important trade and transport link and is therefore of enormous economic importance for Europe. People and goods have been travelling quickly and reliably between Calais and Folkestone for 30 years. A milestone made possible by top technical performance - and the use of high-quality construction materials.

*No longer available, replaced by the products PCI Repaflow, PCI Repaflow plus and PCI Repaflow Turbo.

** Source of information on the Channel Tunnel: 25 years ago: Opening of the Channel Tunnel | Hintergrund aktuell | bpb.de (only available in German)

The history of the Channel Tunnel dates back to the 19th century when the first plans for a fixed connection between England and France were developed. But it took more than 180 years before the project was actually started. In 1986, British Prime Minister Margaret Thatcher and French President François Mitterrand signed the contract to build the Channel Tunnel. Construction began the following year.

A technical challenge

With a total length of around 50 kilometers, including 38 kilometers under the sea, the Channel Tunnel is one of the longest underwater tunnels in the world. Construction at this depth and length placed enormous demands on the construction process. The engineers had to use state-of-the-art technology to bore the tunnel through the English Channel.

The Channel Tunnel comprises three tubes: two for rail traffic and a service tunnel. The service tunnel serves as a safe escape route for passengers and staff, houses important infrastructure for ventilation and enables regular inspections, repairs and maintenance work - without disrupting regular train traffic. In September 1991 and March 1992, PCI advised the builders on the performance grout for the cable grooves in the service tunnel.

Grouting cable grooves in the service tunnel

Cable grooves were integrated into the floor of the service tunnel to lay electrical cables. These cables were used to supply power to inductively guided special vehicles from AEG. Two grooves were milled into each of the existing tracks of the service tunnel. The workers inserted copper cables with PVC hard sheathing into these grooves. These were routed from one carriageway to the other every 2.25 km to enable the crossover sections to be crossed as planned. The cable grooves were then sealed by grouting the joints.

Resistant performance grout from PCI

The English-French construction committee placed strict requirements on the material required. The performance grout had to withstand the load caused by the vehicles regularly driving over it with a total weight of approx. 9 tons. It also had to be non-flammable and able to withstand temperatures from -10 °C to +45 °C. And it had to withstand the salty air with a relative humidity of between 30% and 90%.

Based on these requirements, PCI recommended the performance grout PCI Vergussmörtel 50*. The company Otto Alte-Teigeler GmbH Spezialbau Verkehrsflächen carried out the job on site and filled the grooves with the colored PCI Vergussmörtel 50* performance grout after the cables had been laid. From June 1993 to October 1993, between 5,000 and 6,000 meters were completed every day. In a total of 11,500 hours of precision work, 202,000 meters of induction joints were filled with millimeter precision using laser technology and 15 x 30 mm diamond tools developed for this purpose at the time.

While PCI made the cable grouting in the service tunnel possible with high-quality, permanently functional performance grout, Sika supported the construction of the Channel Tunnel with concrete admixtures for segments and concrete repair products.

Quality that lasts

Since its opening, the Channel Tunnel has developed into an important trade and transport link and is therefore of enormous economic importance for Europe. People and goods have been travelling quickly and reliably between Calais and Folkestone for 30 years. A milestone made possible by top technical performance - and the use of high-quality construction materials.

*No longer available, replaced by the products PCI Repaflow, PCI Repaflow plus and PCI Repaflow Turbo.

** Source of information on the Channel Tunnel: 25 years ago: Opening of the Channel Tunnel | Hintergrund aktuell | bpb.de (only available in German)

Date

01.08.2024

Task

Grouting grooves in the service tunnel

City

Channel Tunnel

Completion

October 1993

Products used

PCI Vergussmörtel 50

Owner

Otto Alte-Teigeler GmbH Spezialbau Verkehrsflächen, 76467 Bietigheim-Baden

Company

PCI Augsburg GmbH

Your contact for inquiries:

PCI Augsburg GmbH

Piccardstraße 11, 86159 Augsburg

Phone +49 821 5901-0

E-Mail: pci-info@pci-group.eu

www.pci-augsburg.de